REFRACTORY SERVICES

REFRACTORY SPECIALISTS SINCE 2007

STRATEGICALLY LOCATED TO SERVE YOU FASTER

OFFERING A FULL RANGE OF REFRACTORY SERVICES

Refractory Inventory

LMB stocks over $ half million in various refractory materials, allowing us to repond quickly to emergencies, and to perform quick change orders during major shutdowns. We stock metallic and ceramic anchors, castables, firebrick, insulating firebrick, ceramic fiber, plastics and mortars, and more.

Design, Engineering & Heat Transfer Calculations

Careful design and engineering is key to the success of your project. We perform extensive calculations and leverage our in-house CAD capabilities to provide "as built" new drawings and modified versions of existing drawings.

Refractory Inspection

Our inspection service includes a detailed inspection report, It identifies repair areas and repair methods, plus recommendations for future repairs based on current refractory conditions.

Refractory Failure Analysis

Our engineers will perform a refractory failure analysis based on a full inspection of your refractory-lined equipment. We back that with mechanical and other services to get you back up and running quickly.

Refractory Brick

Trust LMB’s expert masonry services to deliver the quality design specs, installation procedures and control measures needed to ensure excellent results on your next refractory brick project. LMB masons are experts in rotary kiln brick installations, as well as, many other technical brick installations.

Refractory Shotcrete

Shotcrete has significant cost advantages, better efficiency, better physical properties and improved safety compared to other installation methods. Let our expert craftsmen provide you with quality linings using no-cement, low-cement, conventional and lightweight castables.

Refractory Castable-Forming/Pouring

Our engineers stay at the forefront of refractory technology and are experts in the application of castables. Forming/Pouring utilizes a variety of talents from our highly skilled tradesmen, including welding, carpentry, and either hand pouring our using our Blastcrete castable pumps.

Refractory Gunite

Our custom gunite linings deliver the ultimate in design flexibility. At LMB, we also use a variety of BlastCrete rotary machines and Allentown Gunite Machines. These machines provide LMB the ability to mobilize equipment into difficult areas or stand alone machines on ground level to pneumatically install materials several hundred vertical feet.

Refractory Anchor & Stud Welding

For the ultimate in innovation, LMB is proud to offer Rapid Arc Welding(RAW) by Silicon. LMB is one of few U.S. companies qualified to offer this service. RAW offers unrivaled speed, strength, and engineering. When quality, safety, and project schedules are critical, we use RAW. RAW is not simply studwelding. LMB delivers turnkey welding services for your refractory anchoring and wall stud systems, including new construction and maintenance of your furnaces and related equipment. Our precision design specs, welding skill and quality control procedures deliver exceptional results.

Refractory Ceramic Fiber Linings

Our ceramic fiber lining design and installation services begin with detailed design specifications and installation procedures, combined with our stringent quality control measures. LMB has extensive experience in all forms of fiber installation from stack-bonding to monster modules. Our aim is to ensure your total satisfaction with your ceramic fiber lining project.

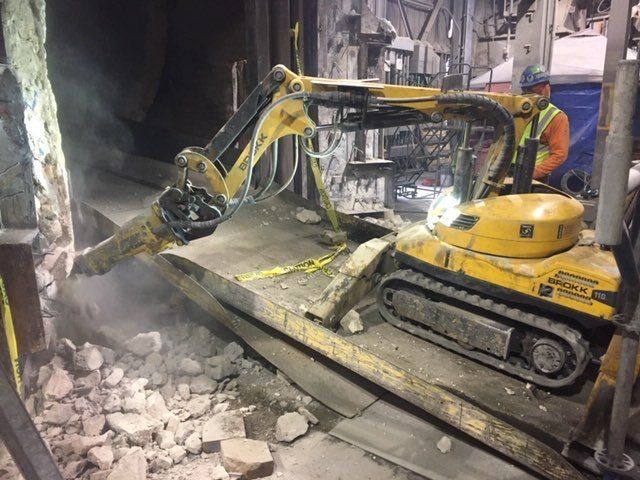

Refractory Demolition

LMB can meet the demands of even the toughest demolition jobs. We utilize Brokk remote control robots to achieve superior efficiency and safety. We demolish and remove concrete, rotary kiln brick and coating, preheater vessels refractory, clinker coolers refractory and more.

Why Choose LMB?

Here are 5 reasons why you'll like our services:

1. Safety

2. Delivery

3. Quality

4. Price

5. Experience

GET THE LMB ADVANTAGE

Contact Us

Thank you for contacting LMB!

We will get back to you as soon as possible.

Please try again later.

WAREHOUSE

JOIN OUR NEWSLETTER

NEWSLETTER SIGNUP Request - LMB Website

Thank you for your interest in our newsletter!

Please try again later.

| LMB Industrial Services, Inc.